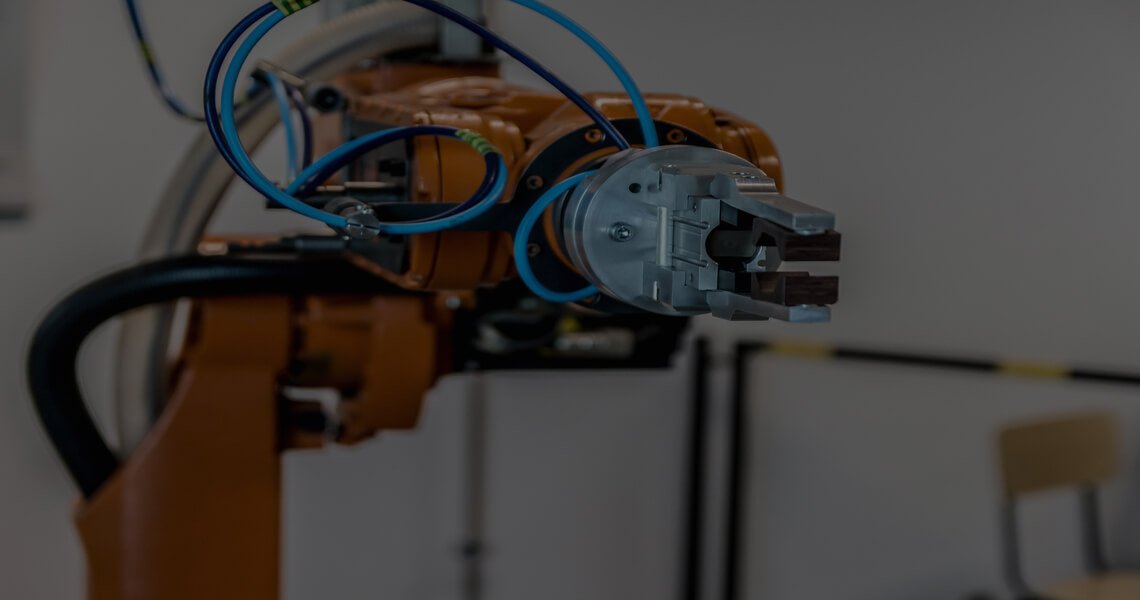

Industrial Automation

Industrial automation is the use of control systems, such as computers or robots, and information technologies for handling different processes and machinery in an industry to replace a human being.

It is the second step beyond mechanization in the scope of industrialization.

Lower Operating Cost

Industrial automation eliminates healthcare costs and paid leave and holidays associated with a human operator.

Further, industrial automation does not require other employee benefits such as bonuses, pension coverage, etc.

Above all, although it is associated with a high initial cost it saves the monthly wages of the workers which leads to substantial cost savings for the company.

The maintenance cost associated with machinery used for industrial automation is less because it does not often fail. If it fails, only computer and maintenance engineers are required to repair it.

Benefits of an Efficient Process Control System

Your business could benefit from a well-designed control system in many ways, including:

- Energy savings – energy wastage is reduced when your plant and machinery are efficiently operated.

- Improved safety – control systems automatically warn you of any abnormalities which minimize the risk of accidents.

- Consistent product quality – variations in product quality are kept to a minimum and reduce your wastage.

- Lower manufacturing costs – detecting faults early means throughput, yield, and quality are maintained.

- Improved environmental performance – systems can give you an early warning of a rise in emissions.

Your business could achieve energy savings of up to 15 percent with a well-designed and properly maintained process control system.